Takeuchi Manufacturing conducts research and development into next-generation forming machines to achieve more-high-precision, delicate forming.

The company has constructed an R&D laboratory and constantly strives to achieve technological improvements, developing forming machines for a range of applications including smartphone cover glass, Fresnel lenses and homogenizers for concentrated solar power applications, thin sheet forming, and heads-up displays.

Takeuchi Manufacturing conducts research and development into next-generation forming machines to achieve more-high-precision, delicate forming.

The company has constructed an R&D laboratory and constantly strives to achieve technological improvements, developing forming machines for a range of applications including smartphone cover glass, Fresnel lenses and homogenizers for concentrated solar power applications, thin sheet forming, and heads-up displays.

Takeuchi Manufacturing can conduct experiments using a wide range of equipment.

Contact us today to see how we can be of service to you.

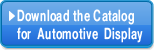

Curved Surface Glass Forming Machine/T-CSGM Series

Approach to nonisothermal forming of curved thin glass.

A information terminals, that is represented by smartphone, have been changing to the wearable style, for example Glass type, Watch type, and such changing began to require using curved shape including smartphone itself. And a curved cover glass (a thin glass which is mounted on the surface of the products) is essential. When Takeuchi s Manufacturing Co.,Ltd. started to develop the machine for thin glass curving, we decided to adopt the nonisothermal forming, the New reheat press method, as this method totally has the advantage of the cost and the quality of the products. At the sametime, we also had been developing the additional special technology to grade up our machine. And finally the partial heating to a glass work became possible and the thermal load to the molds was reduced. These are impossible to realize by the previous reheat press method.

- To develop the high efficient heating system and optimization of the forming condition

- To select the mold material that is no embrittlement even in a high temperature

- To select the method of the surface treatment to the mold, that has no glass fusing.

- To establish the low cost and mass production technology

This machine is suitable not only for wearable information terminal such as smartphone, but also good for glass forming products adapting for vehicles and household electrical appliances. Our experimental machine is good for test production with small quantity and also available for mass production.

Approaches to Advanced Optical System Mass Production

- Fresnel lens (primary side)

- Homogenizer (secondary side)

- Direct press method + proprietary Takeuchi technology

- Duplicating precise shape

- Achieving surface smoothness of sufficient quality

- Keeping costs low and achieving mass production

Rotary Glass Molding Machine

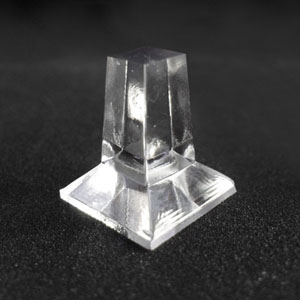

In recent years, the market for high-precision optical glass elements is growing in many cutting-edge fields such as film, telecommunication, nanotechnology, medicine, and biotechnology.

While their high precision and excellent strength combined with superior heat- and light-resistant properties mean glass products are in great demand, high costs and low output quantities make mass production problematic.

Leveraging our wealth of experience with glass press forming, Takeuchi Manufacturing has created the VP-2005, a showcase of our technological achievements. The VP-2005 divides press forming into four stages, enabling mass production.

It performs the press forming process in a vacuum and employs a nitrogen atmosphere for preventing mold oxidation to successfully manufacture high-quality, high-precision products. It also pursues efficiency, using a special heating system to shorten temperature elevation time.

With its significantly increased production efficiency and ability to maintain a stable supply of high-quality, high-precision products, the VP-2005 is a revolutionary forming machine.

Laser lenses

Helical lenses

Power lenses

Micro lenses

Control panels

T-GM Type Glass Molding Machine

(Partnership with RIKEN)

T-GM Type Glass Molding Machine is a high-precision forming machine that employs annealing temperature curve control (path/schedule), which removes residual stress at the target temperature - a condition that is important in order to ensure precision when forming precision glass optical elements -, and a control unit that works in sync with this to adjust oxygen concentration in real time.

- Stroke: 80 mm in normal use

- Pressure: Control range 0.1 to 5 kN

- Method: Infrared ceramic heater

- Temperature: 1000 degrees C or lower in normal use

- Ultimate vacuum: 6 Pa or less

-

*Key technologies

- Weak stress sensing

- Mold contact detection

- Mold cooling speed control

*Improved yield can be expected when used in conjunction with simulation software currently under development.

Materials Testing Machines

(Partnership with Shibaura Institute of Technology, RIKEN)

Capable of performing the tests indicated below on glass materials.

Extremely useful for development of new glass materials.

- Elasto-plastic properties tests: 5 kN (test pressure)

- Creep tests: 5 kN (test pressure)

- Stress-relaxation tests: 5 kN (test pressure)

- Adhesive stress tests: 500 N (test pressure)

Reheat Press

Used in conjunction with an electric furnace for reheat forming experiments.